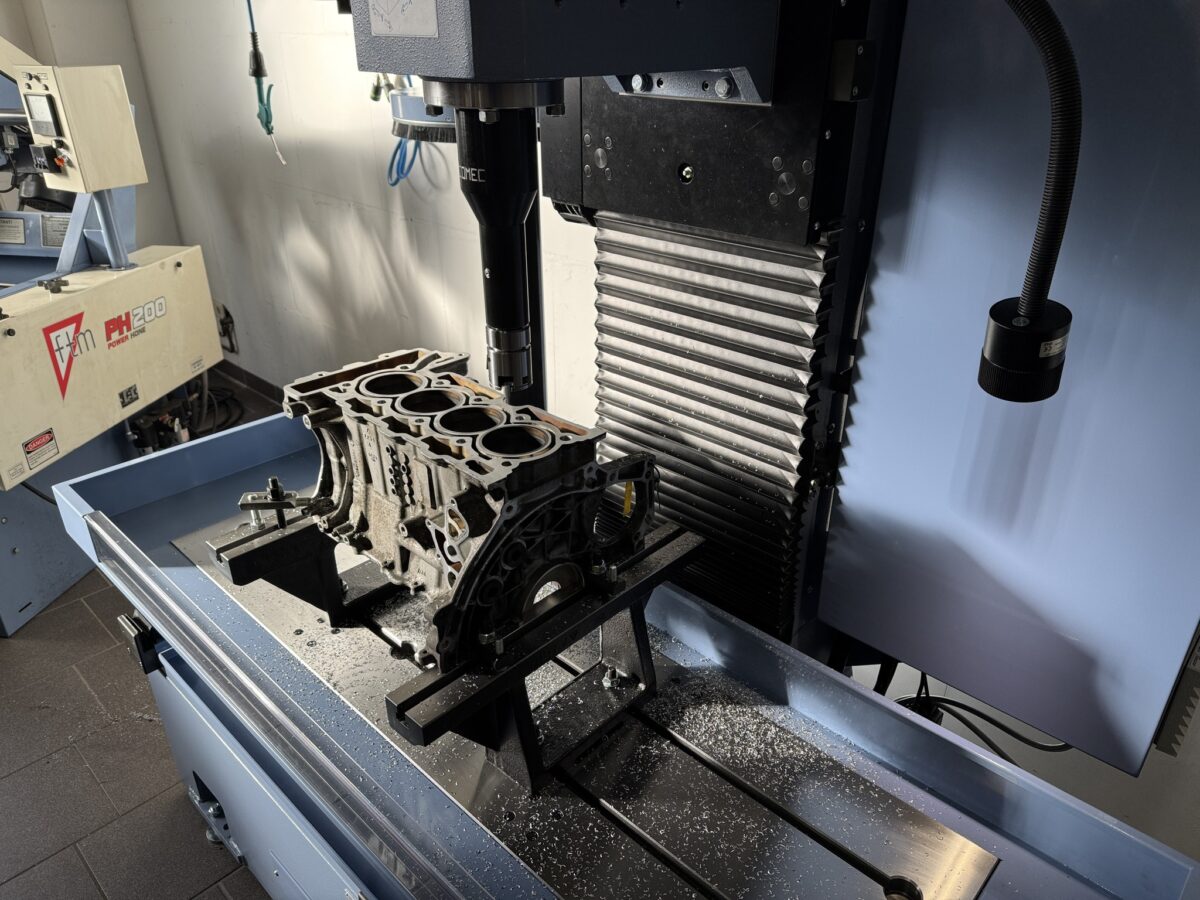

When you bring your MINI to us, you expect more than just “runs again”. It’s about precision, reliability and clean work down to the last detail. This is precisely why we have now expanded our machinery: we have recently started working with a new CNC machine and a fully automatic cleaning system.

What does the new CNC machine do?

The CNC machine enables us to process components much more precisely and reproducibly. This applies, for example:

- Motor and drive components

- Housing and storage areas

- Fits and flat surfaces

Instead of time-consuming, manual settings, many things are now automated and laser-supported. That means for you:

- Higher dimensional accuracy

- Consistent quality even for series production

- Less risk due to manual errors

In short, the machine doesn’t take responsibility away from us, but it does give us better tools to deliver your MINI the way we would expect it to be delivered.

Professional cleaning system for components

At the same time, a new cleaning machine has moved in with us. Engine, gearbox and peripheral components are cleaned thoroughly and evenly before further processing. This has two major advantages:

- Dirt, oil and residues are reliably removed

- Subsequent work such as measuring, processing and assembly becomes more accurate and safer

Clean parts are the basis for a clean repair – especially with overhauled or modified components.

How does this benefit you as a customer?

For you, the investment means three things above all:

- More precision

Automated and laser-supported processes allow us to work more closely to tolerances and adapt components even more precisely. - Better reproducibility

Work that we carry out regularly can be realised with the new technology in a stable and repeatable manner at the same level of quality. - More efficient processes

The machines save us several hours of pure adjustment and manual labour per head. We can invest this time more sensibly in diagnostics, detailed work and quality assurance – in other words, precisely in the areas that ultimately determine the riding experience and durability.

Investing in the future of your MINI

For us, the new technology is not a “showroom toy”, but a tool that will be in daily use. Step by step, we are continuing to build up our machinery so that we can offer you long-term support:

- Specialised work on the MINI

- High-quality overhauls

- and clean, reproducible results

can offer.

If you have any questions about specific work or would like to know what we can specifically improve with the new technology in your MINI, please get in touch with us – as always by email, WhatsApp or directly via the website.